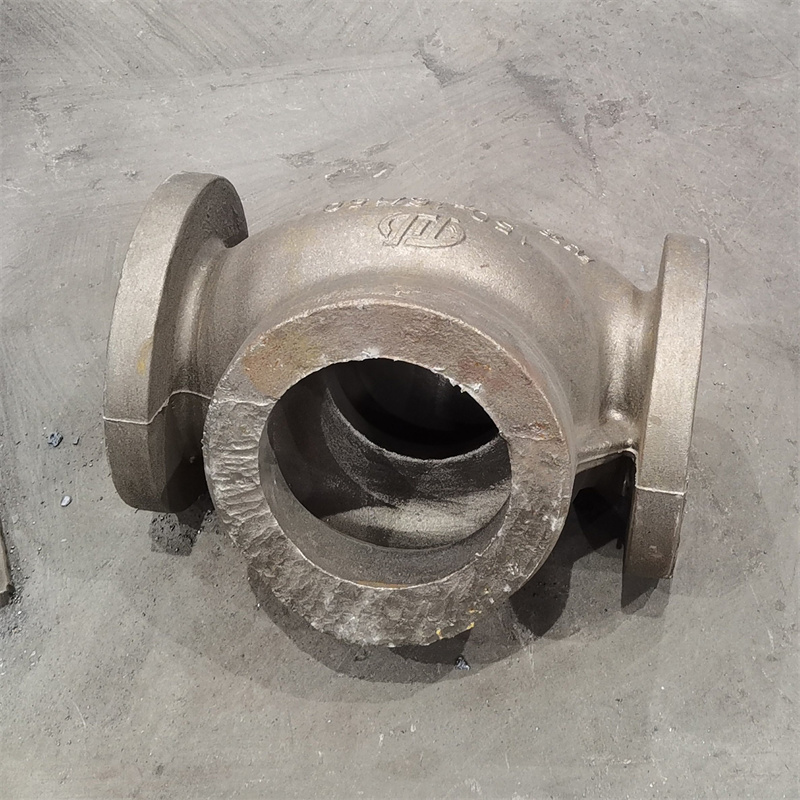

Cone Bowl for Decanter Centrifuge

Product Specification

Product Name | Cone Bowl for Decanter Centrifuge |

Casting Method | Centrifugal casting |

Material Options | 304, 304L, 316, 316L, SAF2304, SAF 2205, SAF2507 |

Material Standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

Casting Weight | 100-15000 kg |

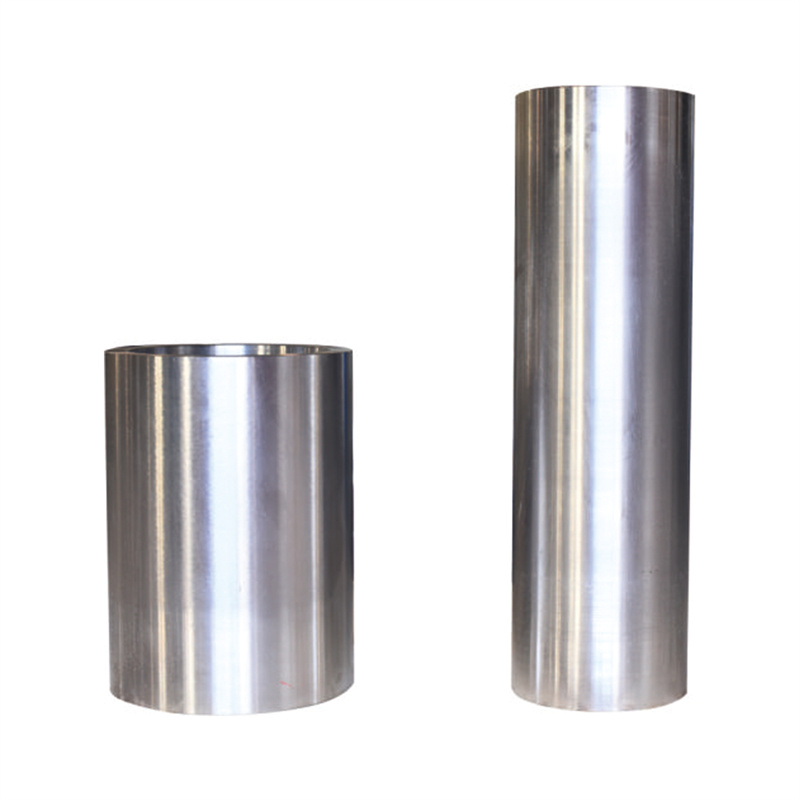

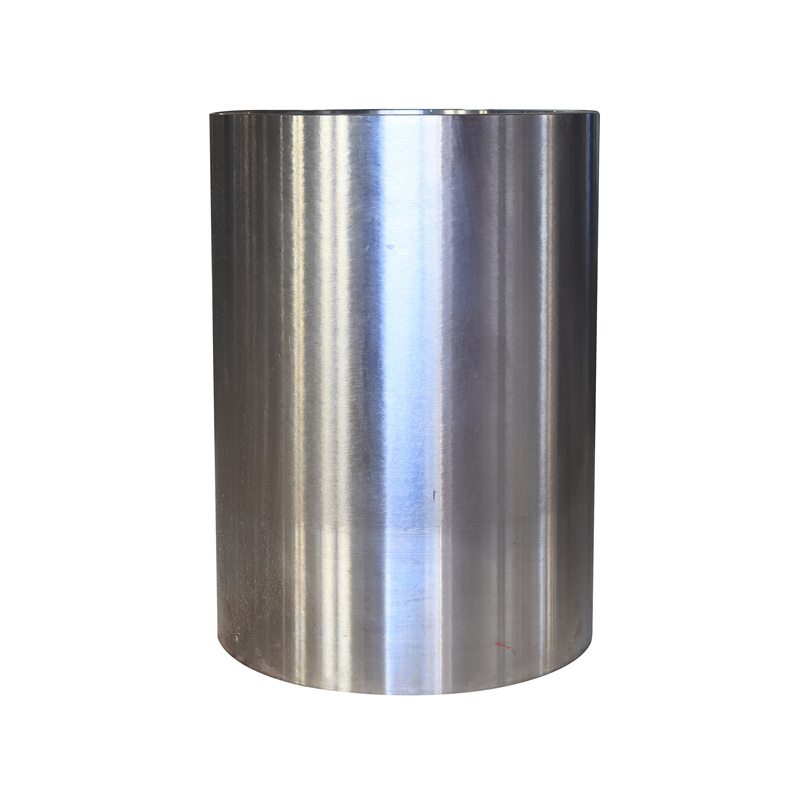

Casting Size | Max Diameter: 1600 mm, Max Length: 4200 mm |

Casting Dimension Tolerance | CT9 - CT12 |

Casting Surface Roughness | Ra 12.5∽Ra50 um |

Machining Surface Roughness | Ra0.8 ~ 6.3um |

Heat treatment | Annealing, normalizing, quenching or tempering |

Finish | As cast, rough machined, finish machined. |

Service Available | OEM & ODM |

Certification | CE, ISO9001:2015, ISO19600:2014, ISO14001:2015, ISO45001:2018, |

Application | Decanter centrifuge, pusher centrifuge, disc separator, separation machine etc. |

Production Process

Centrifugal casting is a technology and method that injects liquid metal into a high-speed rotating mold, causing the metal liquid to undergo centrifugal motion to fill the mold and form the casting. Due to centrifugal force, liquid metal can fill the mold radially and form a free surface of the casting. Without a core, cylindrical inner holes can be obtained, which helps to eliminate gases and inclusions in the liquid metal which may affect the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Smelting and AOD Refining

Weizhen is uniquely equipped with AOD furnace for the refining of molten metal besides normal medium-frequency induction furnaces. The molten metal after refining is much more pure with super low carbon, phosphorus, and sulfur content, providing uniform and perfect mechanical and chemical properties for the cast parts.

Pouring & Casting

The molten metal is poured into a cylindrical mold that rotates at a high speed. The centrifugal force generated by the rotation forces the molten metal to spread evenly along the inner surface of the mold, creating a hollow, cylindrical shape as it solidifies. Centrifugal force causes impurities and lighter oxides to migrate to the inside diameter of the casting which, upon solidification, are easily removed by CNC machining and processing.

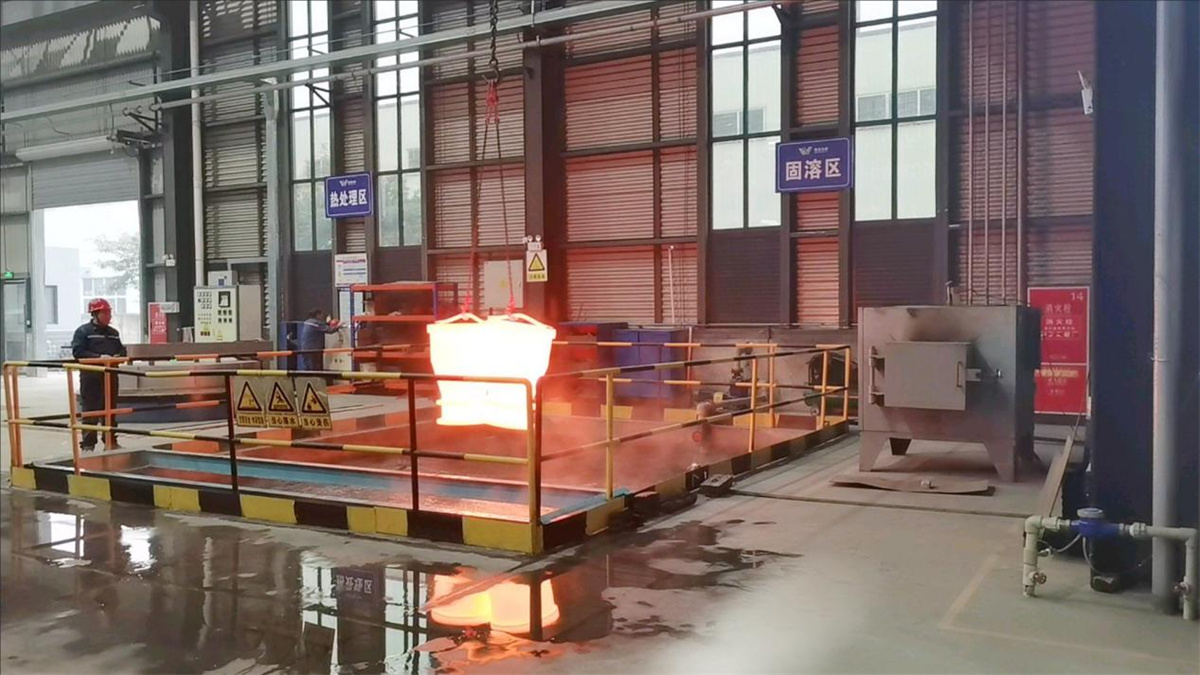

Heat Treatment

Heat treatment is critical to the properties and quality of the steel castings. Weizhen is equipped with advanced 1200 °C heat furnaces and car type furnaces for the heat treatment. The casting parts are precisely heat treated to achieve the desired properties inside the factory.

Machining

The centrifugal casting blanks need to be further machined & processed to meet customer requirements. Weizhen is equipped with all sorts of machining equipment for the processing of stainless steel casting parts and components. State-of-the-art cutting machine, shot blasting machine, horizontal lathe, CNC horizontal lathe, CNC vertical lathe, CNC Gantry milling machine, Radial drilling machine, Digital display boring and milling machine are all installed in the factory. The products could be delivered as cast, rough machined or finish machined.

Inspection & Testing

Casting parts need to be tested and inspected before delivering to customer. Weizhen conducts strict checking and testing through out the whole production process to ensure best product quality and customer satisfaction. The tests and inspections Weizhen provides include, but not limited to, chemical analysis, physical properties, dimensions, PT, RT, three coordinates, 3D Scan.