our customersWelcome to cooperate with us

Weizhen Hi-Tech, a premier stainless steel foundry from China, stands as the unanimous choice among leading global players across separation, process engineering, fluid handling, and energy industries. Our expertise in manufacturing large, complex stainless steel castings has earned us over 60% of the world market share in the decanter centrifuge bowl segment, and we continue to expand our reach in providing essential components for pump & valve systems, pulp & paper machinery, as well as seawater desalination, marine, and offshore industries. Emphasizing sustainability and environmental stewardship, Weizhen is committed to innovative practices that meet the highest industry standards.

OUR MAIN PRODUCT LINES

Weizhen offers a wide range of centrifugal casting and sand casting stainless steel components and parts with customized chemical composition and design. Our highly professional engineers are always ready to help customers to get the right stainless steel casting products, whether it be decanter bowl, separator drum, impeller, rotor, or pump volute, valve body or stainless steel casing.

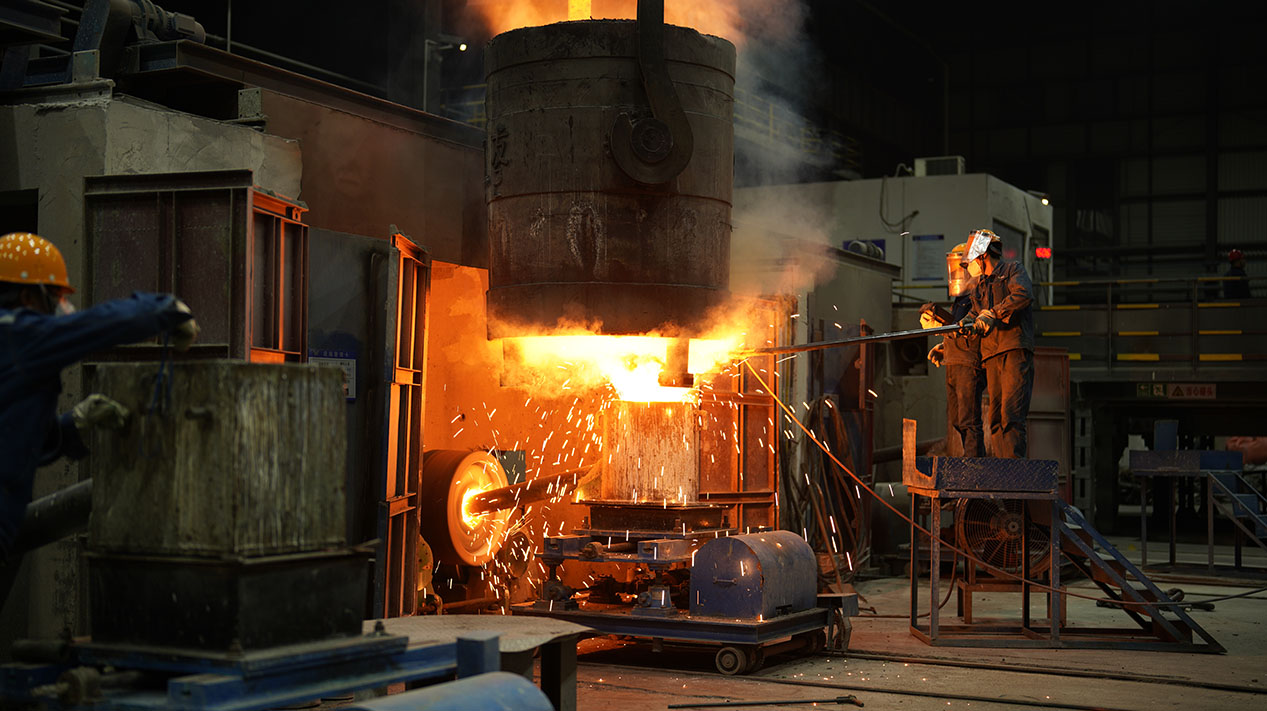

Smelting & Refining

+

Customized material options with in-house Intermediate frequency smelting furnaces and AOD refining furnace.

Centrifugal Casting

+

Industry leader in stainless steel centrifugal casting in large diameters with extensive experiences and industrial know-how.

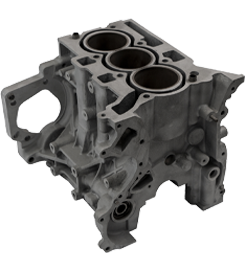

Sand Casting

+

Expert in sand casting of large size stainless steel parts up to 15000kg per casting.

CNC Machining

+

Fully set-up CNC machining capabilities that handles cutting, drilling, boring, milling, turning, grinding, polishing etc.

Material Customization

+

In-house smelting & refining capabilities enable Weizhen provide extensive tailored material options.

01

Expert Team

Professional team with 5 consulting industry experts & 40 + full-time engineers.

02

Industry Standards Drafter

Main drafter of National Industry Standards for Decanter Centrifuge Bowls.

03

Technology & Innovation

Customized solution provider. Strong innovation capabilities with 30+ Patents.

04

Quality Management System

Fully certified with ISO9001, ISO14001, ISO19600, OHSAS18001 management system.

05

Full Process Quality Control

Full online quality inspection and control system from materials to final products.

06

NDT Testing

All casting products are fully tested before shipment, including chemical & physical properties, PT, RT, UT, etc.

contact us

STAY IN TOUCH

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Inquiry Now