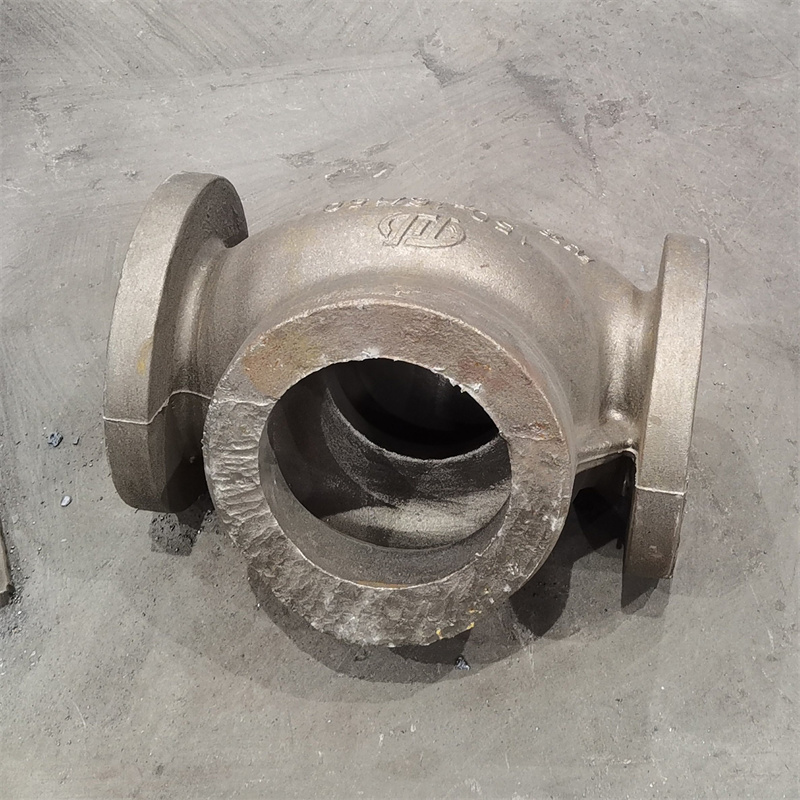

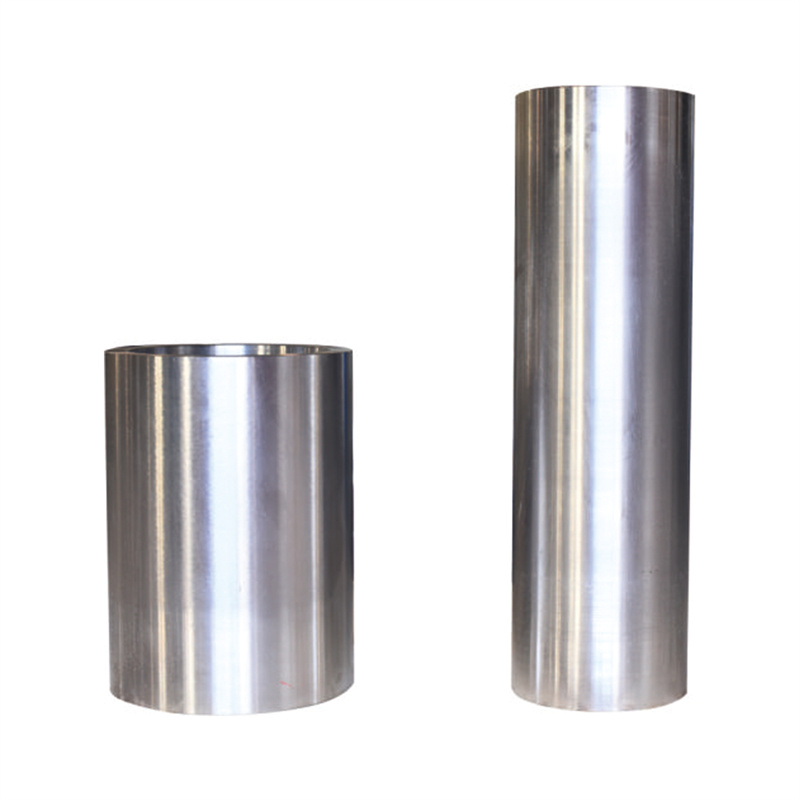

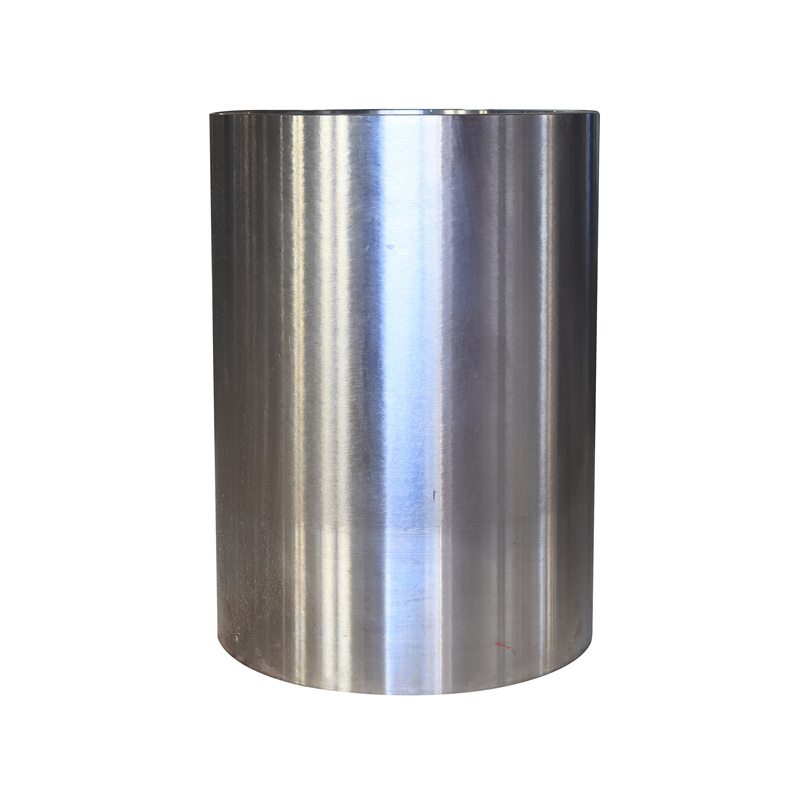

Duplex Stainless Steel Cylindrical Bowl for Decanter Centrifuge

Product Specification

- Material: 2205(022Cr22Ni5Mo3N),NAS 329J3L, UNS S32205/S31803 DIN/EN 1.4462, ASTM A240, ASME SA-240.

- Size: Max. Diameter: 1600mm, Max. Length: 4200mm.

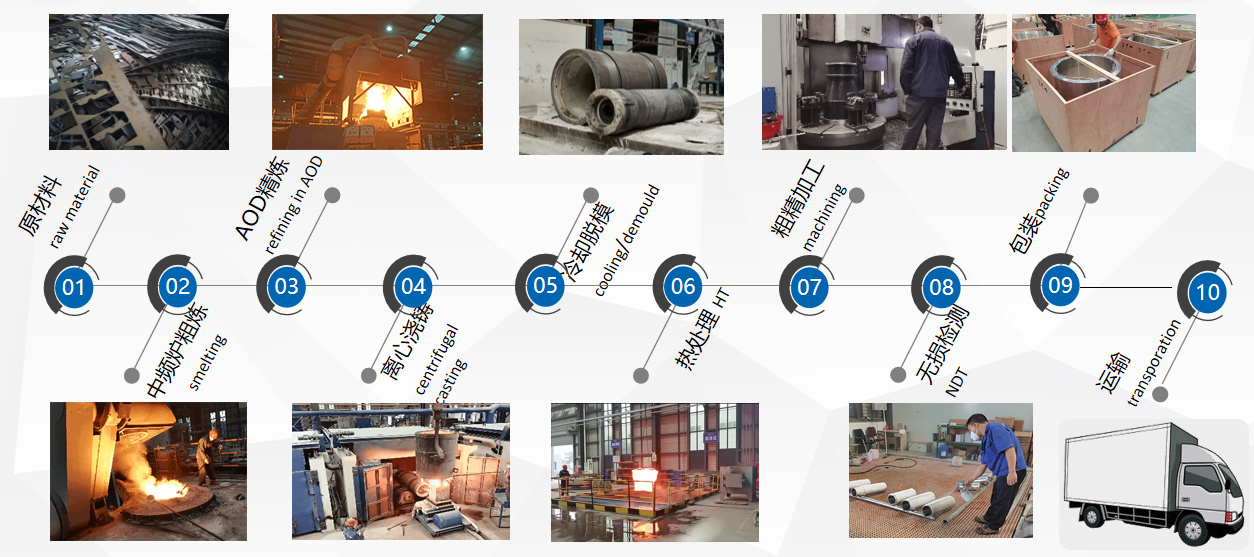

- Processing: Smelting, Refining, Centrifugal casting, Heat treatment, machining, testing.

- Heat treatment: Annealing, normalizing, quenching or tempering

- Finish:Cast, rough machined, finish machined.

Product Name | Duplex Stainless Steel Cylindrical Bowl for Decanter Centrifuge |

Casting Method | Centrifugal casting |

Material Options | Austenitic stainless steel, martensitic stainless steel, duplex steel, nickel based stainless steel |

Material standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

Casting weight range | 100-1500 kg |

Casting Size range | Max linear size: 4200 mm, Max diameter size: 1600 mm |

Casting dimension tolerance | CT9 - CT12 |

Casting surface roughness | Ra 50∽Ra12.5 um |

Machining surface roughness | Ra0.8 ~ 6.3um |

Service available | OEM & ODM |

Quality control | ISO9001:2014, CE EN |

Application | Decanter centrifuge, pusher centrifuge, disc separator, separation machine etc. |

Production Process

Weizhen Hi-tech has full in-house facilities for centrifugal casting manufacturing. Weizhen is uniquely equipped with AOD furnace for the refining of molten metal. A super low carbon, phosphorus, and sulfur content Steel alloy could be made upon request.

Weizhen has the largest horizontal centrifugal casting machine and vertical centrifugal casting machine in China. The maximum casting diameter could be as long as 1600mm. The single biggest collection of more than 300 centrifugal casting molds enables Weizhen to meet any size requirements.

Weizhen has full set up for machining and testing. The parts can be delivered as cast, rough machined or finish machined. Chemical, physical properties, sizes, and NDT test could be all done inside the factory.

What is Centrifugal Casting ?

Centrifugal casting is a method used to produce metal products that are tubular, cylindrical, or annular in shape that require high quality, purity, and structural uniformity. Molten metal is poured into a spinning mold which forces the molten metal to the mold wall. The process is precisely monitored and controlled to assure the correct volume of metal is poured at the calculated flow rate and temperature. As the metal is poured, it conforms to the inside diameter of the mold and solidifies as it cools. Once solidified, the casting can be heat-treated, cut, and machined to customer specifications.

Advantages Of Centrifugal Casting Stainless Steel Bowl

- Uniform Grain Structure:Centrifugal casting produces a uniform grain structure in the stainless steel, which results in improved mechanical properties and enhanced performances for the stainless steel parts.

- High Density:The centrifugal force helps eliminate air bubbles and impurities in the molten metal, resulting in a high-density, defect-free product.

- Improved Strength:Stainless steel bowls produced through centrifugal casting tend to have improved tensile strength and wear resistance compared to other casting methods.

- Wall Thickness Control:The rotation speed and the duration of the casting process can be adjusted to control the wall thickness of the stainless steel bowl, allowing for precise customization.

- Material Versatility:Various types of stainless steel could be chosen in centrifugal casting to meet specific requirements for corrosion resistance, heat resistance, and other properties.

Get Your Customized Solutions