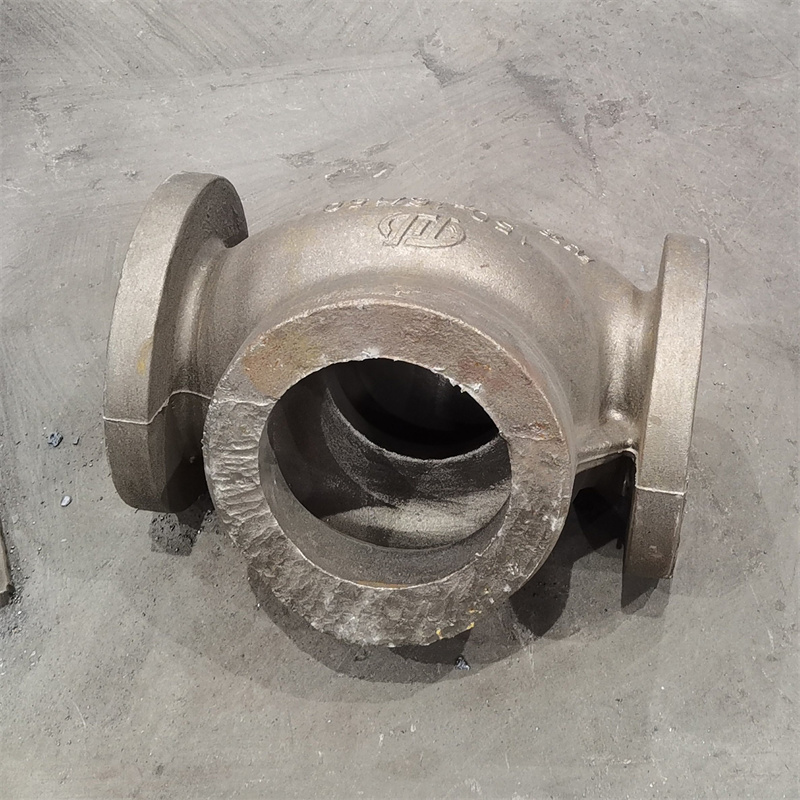

End Hub for Decanter Centrifuge

Product Specification

Product Name | End Hub |

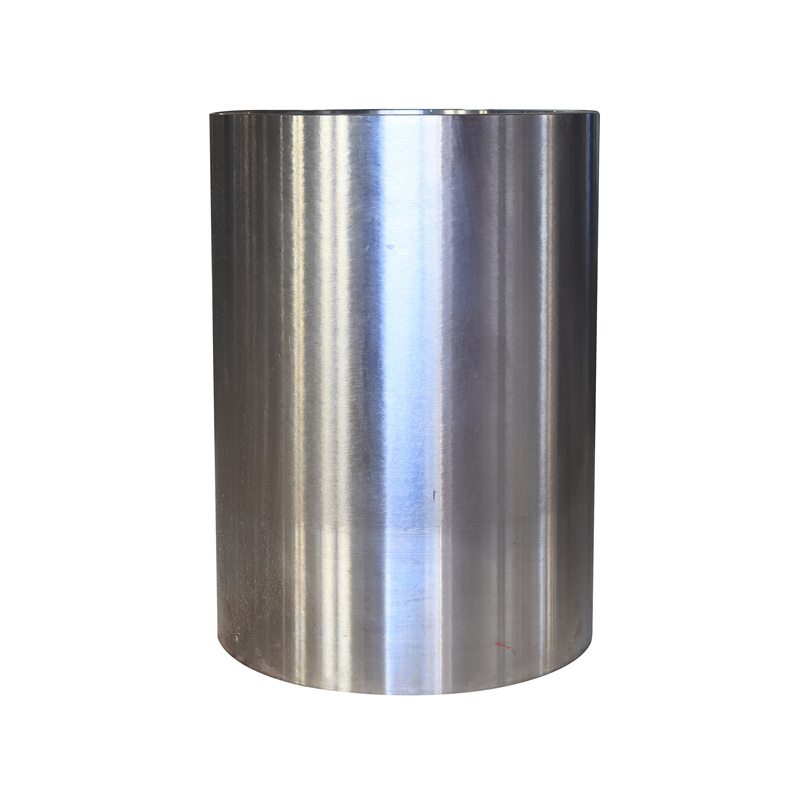

Casting Method | Centrifugal casting |

Material Options | 304, 304L, 316, 316L, SAF2304, SAF 2205, SAF2507 |

Material Standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

Casting Weight | 100-15000 kg |

Casting Size | Max Diameter: 1600 mm, Max Length: 4200 mm |

Casting Dimension Tolerance | CT9 - CT12 |

Casting Surface Roughness | Ra 12.5∽Ra50 um |

Machining Surface Roughness | Ra0.8 ~ 6.3um |

Heat treatment | Annealing, normalizing, quenching or tempering |

Finish | As cast, rough machined, finish machined. |

Service Available | OEM & ODM |

Certification | CE, ISO9001:2015, ISO19600:2014, ISO14001:2015, ISO45001:2018, |

Application | Decanter centrifuge, pusher centrifuge, disc separator, separation machine etc. |

What is Centrifugal Casting?

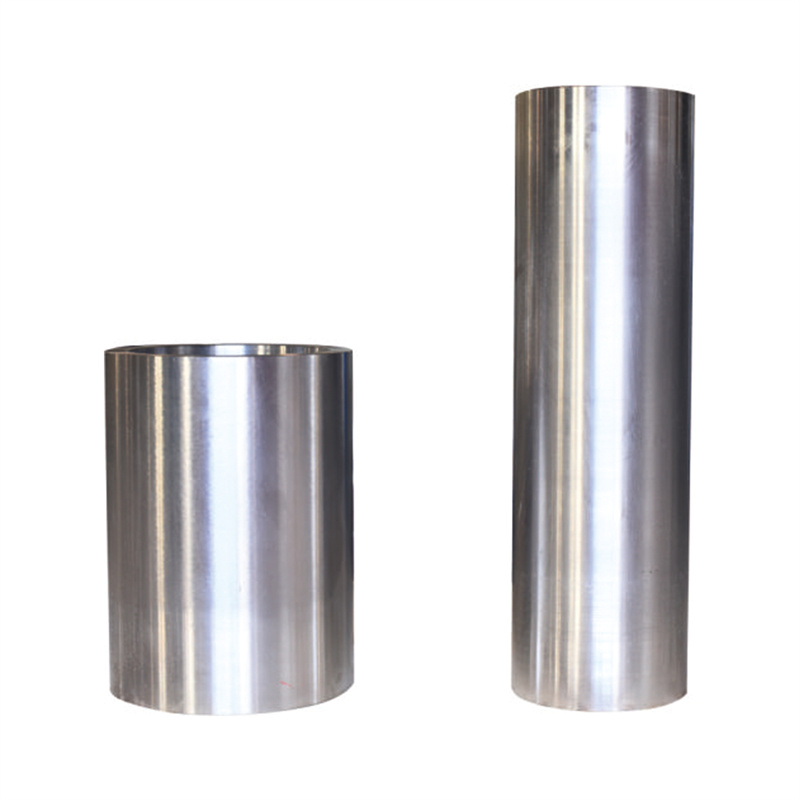

Centrifugal casting is a method used to produce metal products that are tubular, cylindrical, or annular in shape that require high quality, purity, and structural uniformity. Molten metal is poured into a spinning mold which forces the molten metal to the mold wall.

The process is precisely monitored and controlled to assure the correct volume of metal is poured at the calculated flow rate and temperature. As the metal is poured, it conforms to the inside diameter of the mold and solidifies as it cools. Once solidified, the casting can be heat-treated, cut, and machined to customer specifications.

Unique Strengths of Weizhen Hi-tech

Weizhen Hi-tech has profound industrial know-how and experience in the manufacture of the major casting parts used in decanter centrifuges. Weizhen has a full service expert engineer team and is equipped with most advanced manufacturing facilities. Weizhen is now a reliable and trust-worthy partner for many world leading decanter centrifuge manufacturers around world.

PCM Sand 3D Printing Technology

- ♦ Directly print sand pattern or mold without making mold.

- ♦ High complex casting with high precision.

- ♦ Cost effective for prototypes and small batch manufacturing.

- ♦ Short lead time.

Advanced Manufacturing & Inspection Facilitie

- ♦ Fully set up CNC machining capabilities

- ♦ In-house inspection & testing equipment

- ♦ Hassle free One-stop service

Extensive Collection of Molds

- ♦ Huge collection of centrifugal casting molds, covering most of the sizes in the market.

- ♦ Large size capability. Up to 15000Kg

Maximum Diameter: 1600mm,

Maximum Length: 4200mm. - ♦ Cost saving with shorter lead time

AOD Refining Furnace

Weizhen is uniquely equipped with AOD furnace for the refining of molten metal. The molten metal is much more pure after refining with super low carbon, phosphorus, and sulfur content, providing better mechanical and chemical properties.

Weizhen can pour and cast super low carbon steel, duplex stainless steel, super duplex stainless steel, nickel based steel with quality guaranteed.

Certification

With committed responsibilities to customer, employees, the society, and the environment, Weizhen is certified and strictly operates with multiple management systems to ensure a sustainable future. The main certification includes ISO9001 quality management system, EU product CE certification, ISO14001 environmental management system certification, OHSAS18001 occupational health and safety management system certification, GB/T29490 intellectual property management system certification, and ISO19600 compliance management system certification.