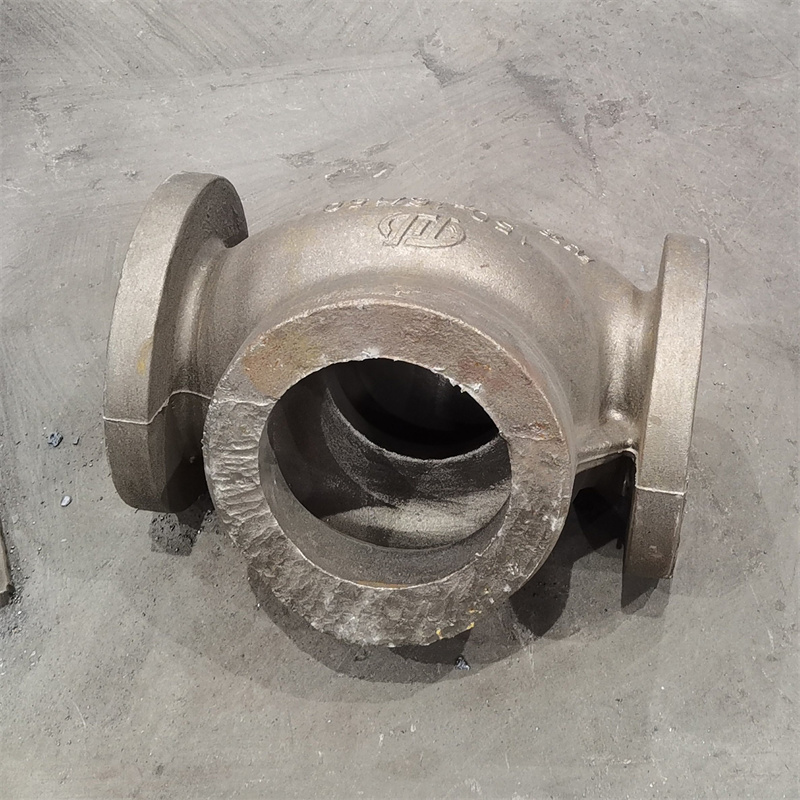

Centrifugal Casting Stainless Steel Drum for Decanter Centrifuge

Product Specification

- Material: Austenitic Stainless Steel, Martensitic Stainless Steel, Duplex & Super Duplex Stainless Steel, Ferric Stainless Steel,

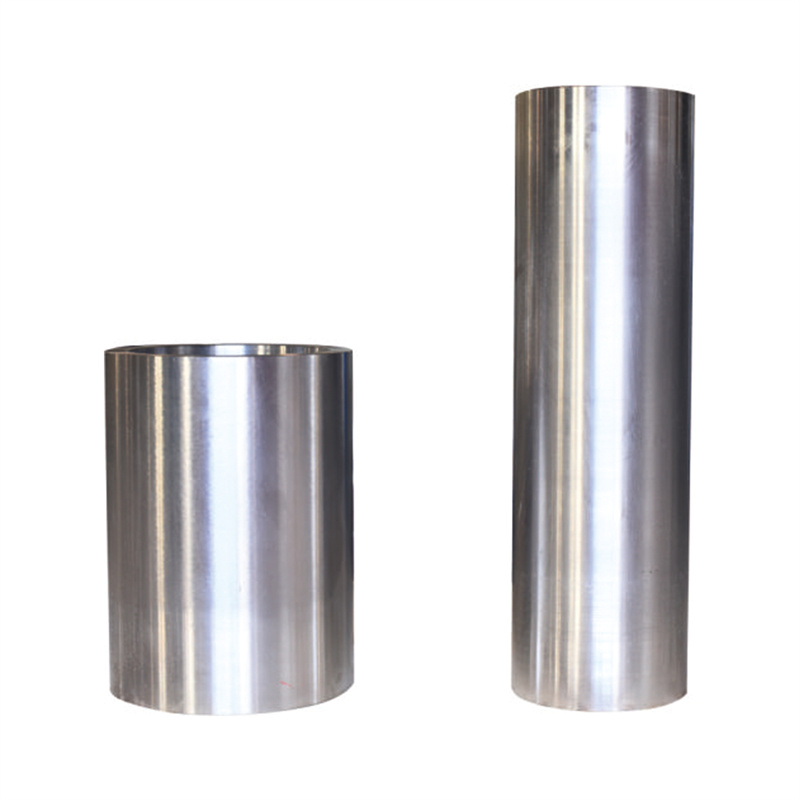

- Size: Max. Diameter: 1600mm, Max. Length: 4200mm.

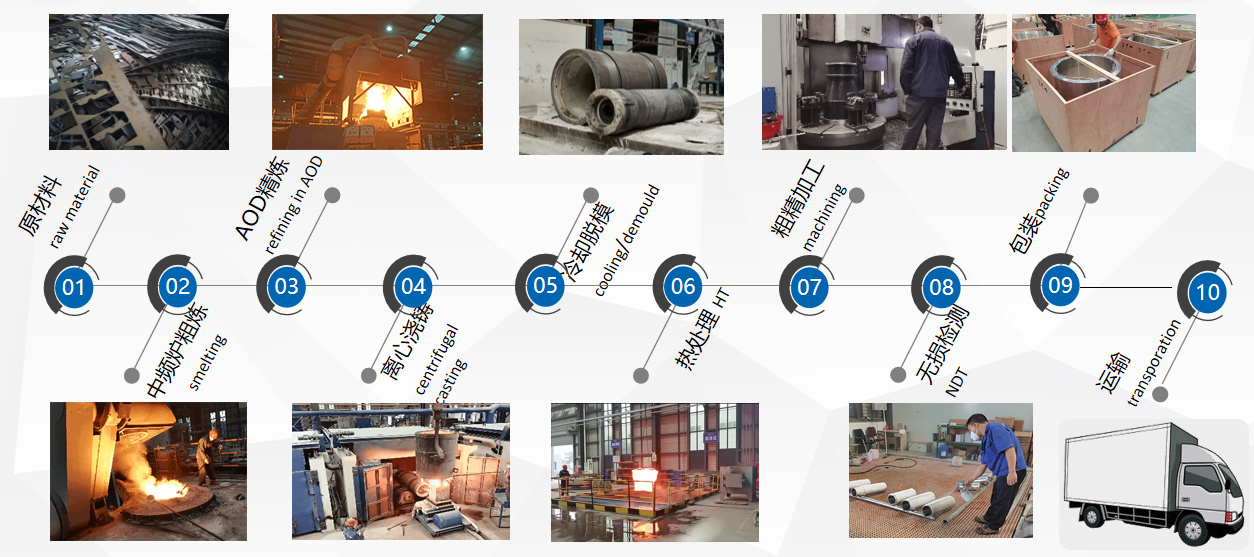

- Process: Process designing, Casting simulation, Smelting, Refining, Pouring & centrifugal casting, Heat treatment, machining, testing, packing.

- Heat treatment: Annealing, normalizing, quenching or tempering

- Finish:Cast, rough machined, finish machined.

Product Name | Centrifugal Casting Stainless Steel Drum for Decanter Centrifuge |

Casting Method | Centrifugal casting |

Material Options | 304, 304L, 316, 316L, SAF2304, SAF 2205, SAF2207 |

Material Standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

Casting Weight | 100-1500 kg |

Casting Size | Max Diameter: 1600 mm, Max Length: 4200 mm |

Casting Dimension Tolerance | CT9 - CT12 |

Casting Surface Roughness | Ra 50∽Ra12.5 um |

Machining Surface Roughness | Ra0.8 ~ 6.3um |

Service Available | OEM & ODM |

Certification | CE, ISO9001:2015, ISO19600:2014, ISO14001:2015, ISO45001:2018, |

Application | Decanter centrifuge, pusher centrifuge, disc separator, separation machine etc. |

Production Process

Centrifugal casting parts manufacturing involves a series of production processes in order to get finish products from raw materials. Weizhen Hi-tech has full in-house production facilities for the whole process, which strengthens Weizhen’ s abilities to meet customer processing needs with consistent stringent quality control and quick turnaround time.

Smelting and AOD Refining

Besides normal medium-frequency induction furnaces, Weizhen is uniquely equipped with AOD furnace for the refining of molten metal. The molten metal after refining is more pure with super low carbon, phosphorus, and sulfur content, thus providing better mechanical and corrosion-resistant properties.

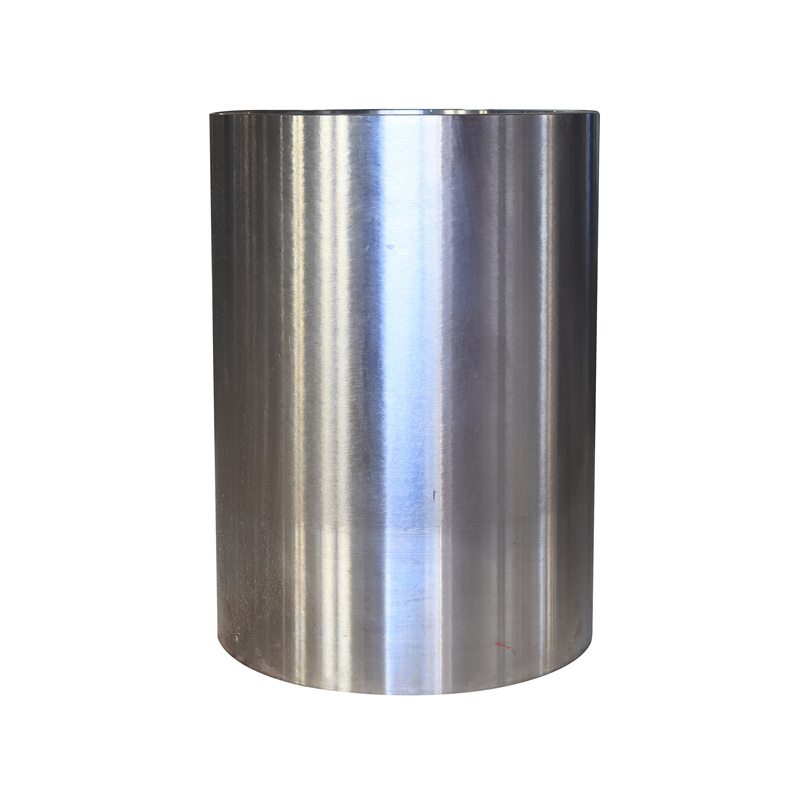

Centrifugal Casting

Weizhen is equipped with both horizontal centrifugal casting machine and vertical centrifugal casting machine. The maximum casting diameter is 1600mm and length up to 4200mm. Weizhen possesses a large collection of centrifugal casting molds and is ready to cast virtually any size required in the market.

Heat Treatment

Machining

Weizhen is equipped with over 20 machines for the processing of stainless steel casting parts and components. State-of-the-art cutting machine, shot blasting machine, horizontal lathe, CNC horizontal lathe, CNC vertical lathe, CNC Gantry milling machine, Radial drilling machine, Digital display boring and milling machine are all installed in the factory.

The fully set up facilities enables Weizhen to provide customers with a highly convenient and efficient one stop service. The parts can be delivered as cast, rough machined or finish machined.

Testing

Product quality test is essential in the centrifugal casting industry for customer satisfaction. Weizhen conducts strict checking and testing through out the whole production process. Weizhen runs a series of chemical and physical testing, NDT testing, dimensional inspection to ensure each product meet customer requirements or standards.