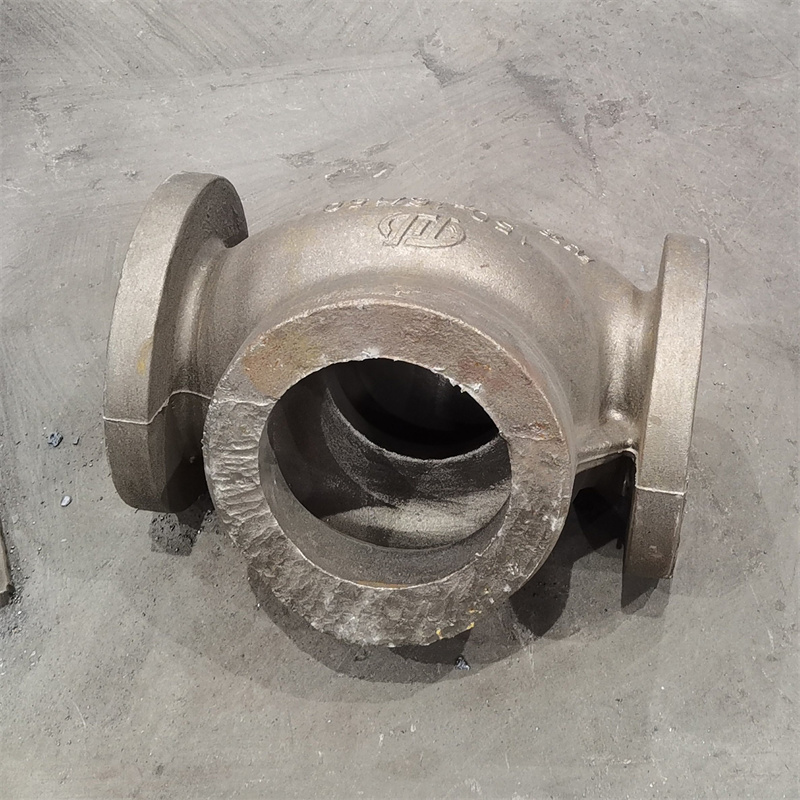

Duplex Stainless Steel Volute

Product Specification

- Material: Duplex stainless steels, super duplex stainless steel, Austenitic, nickel-based alloys.

- Size: Max. Length: 5200mm, Max. Width: 4300mm.

- Process: Mold Making, Casting simulation, Smelting, Refining, Pouring, Heat treatment, machining, testing, packing.

- Heat treatment: Annealing, normalizing, quenching or tempering

- Finish:Cast, rough machined, finish machined.

Product Name | Duplex Stainless Steel Volute |

Casting Method | Sand Casting |

Material Options | Duplex stainless steel, EN1.4362, EN 1.4462, EN1.4410, 304, 316, 316L. |

Material Standard | GB, ASTM, AISI, EN, DIN, BS, JIS, NF, AS, AAR, |

Casting Weight | 100-1500 kg |

Casting Size | Max Length: 5200 mm, Max Width: 4300 mm |

Casting Dimension Tolerance | CT9 - CT12 |

Casting Surface Roughness | Ra 50∽Ra12.5 um |

Machining Surface Roughness | Ra0.8 ~ 6.3um |

Service Available | OEM & ODM |

Certification | CE, ISO9001:2015, ISO19600:2014, ISO14001:2015, ISO45001:2018, |

Application | Seawater pump, slurry pump, split pump,chemical pump, |

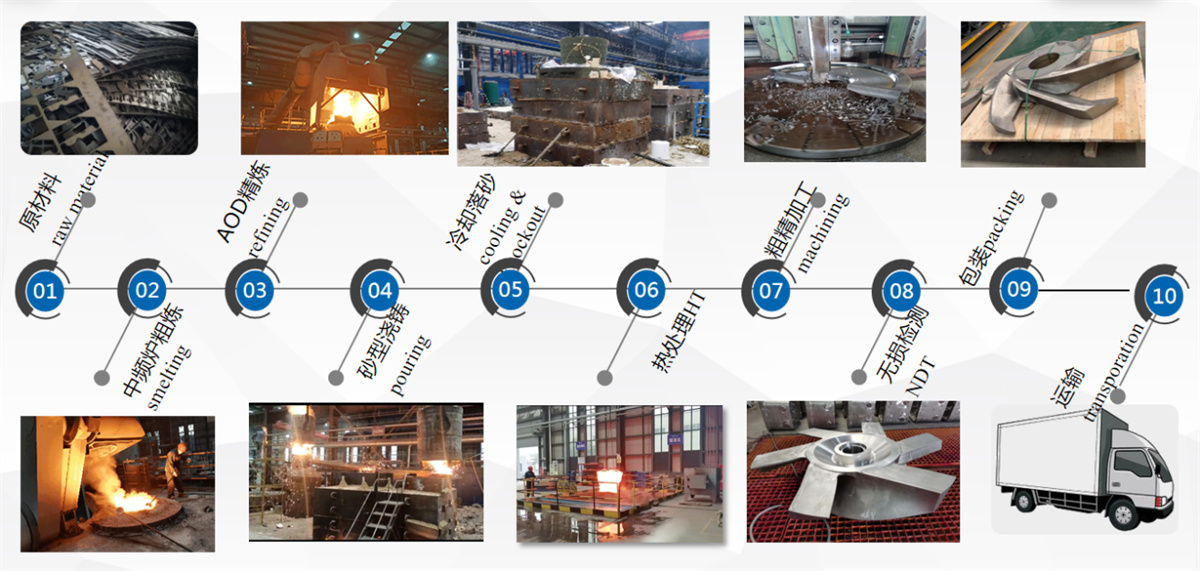

Production Process

Stainless steel casting parts manufacturing involves a series of production processes in order to get finish products from raw materials. Weizhen Hi-tech has full in-house production facilities for the whole process, which strengthens Weizhen’ s abilities to meet customer needs with consistent quality control and quick turnaround time.

PCM 3D Printing

PCM stands for Patternless Casting Manufacturing. PCM 3D Printing technology does not require molds for manufacturing complex casting parts. It directly prints sand molds from digital data. It is highly efficient for new product development and delivery of multiple variety, small batches of products in less time and at lower cost.

PCM 3D Printing technology makes integrated molding of complex structures in a whole with better accuracy than traditional sand casting, providing significant comprehensive economic benefits. 3DP mold free sand printing technology can reduce casting manufacturing costs by more than 30% and production cycles by more than 50%.

Weizhen Hi-tech is equipped with four sets of cutting-edge sand 3D printing machine. The maximum printing size is up to 2200 x 1000 x 800mm. High complex castings and or small batch castings could be supplied timely and economically.

Smelting and AOD Refining

Weizhen is uniquely equipped with AOD furnace for the refining of molten metal. The molten metal after refining is much more pure with super low carbon, phosphorus, and sulfur content, providing better mechanical and chemical performances. Weizhen can pour and cast super low carbon steel, duplex stainless steel, super duplex stainless steel, nickel based steel with quality guaranteed.

Pouring & Casting

Weizhen is focused on large size high complex stainless steel casting. The maximum casting weight is up to 15000kgs. Weizhen is especially good at casting of duplex stainless steel, super duplex stainless steel, Austenitic stainless steel and nickel based steel. The main alloy number include NAS 329J3L, UNS S32205/S31803, DIN/EN 1.4462, ASTM A240, ASME SA-240, 2304, S32003, 2205, 2507, S32707, UNSS32304, EN1.4362, S32205-EN1.4462, S32750, EN1.4410, etc.

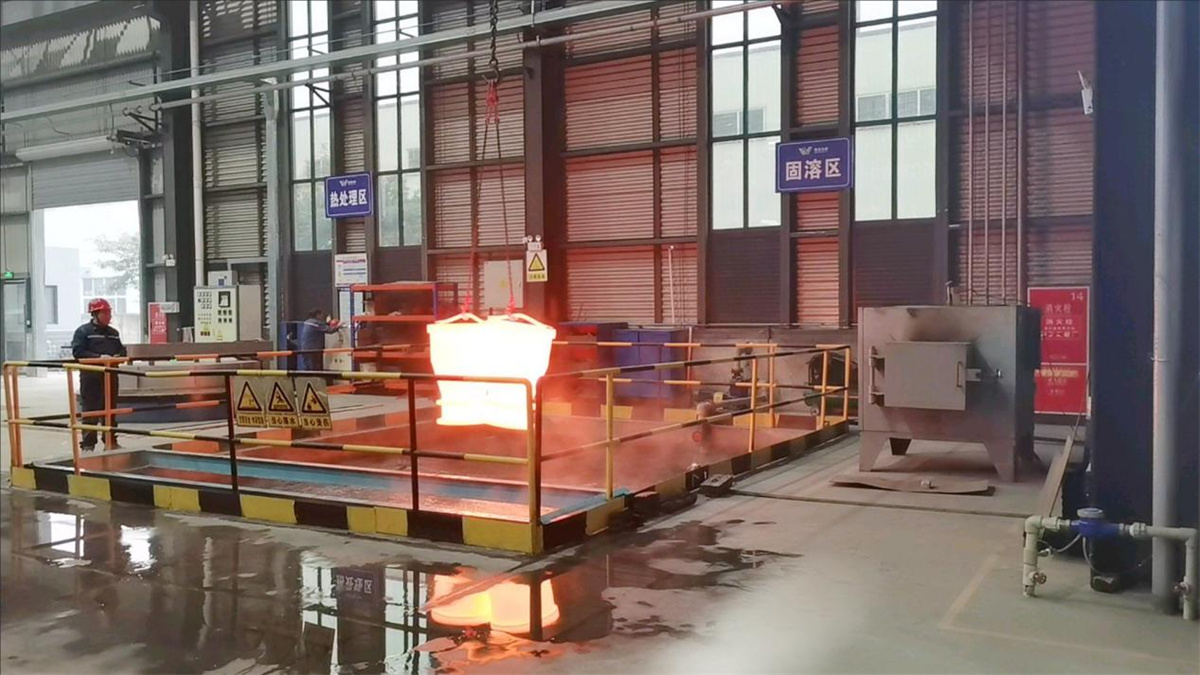

Heat Treatment

Heat treatment is critical to the properties and quality of steel castings. Weizhen is equipped with advanced 1200 °C heat furnaces and solution pools. The casting parts are precisely heat treated and solution annealed to achieve desired properties.

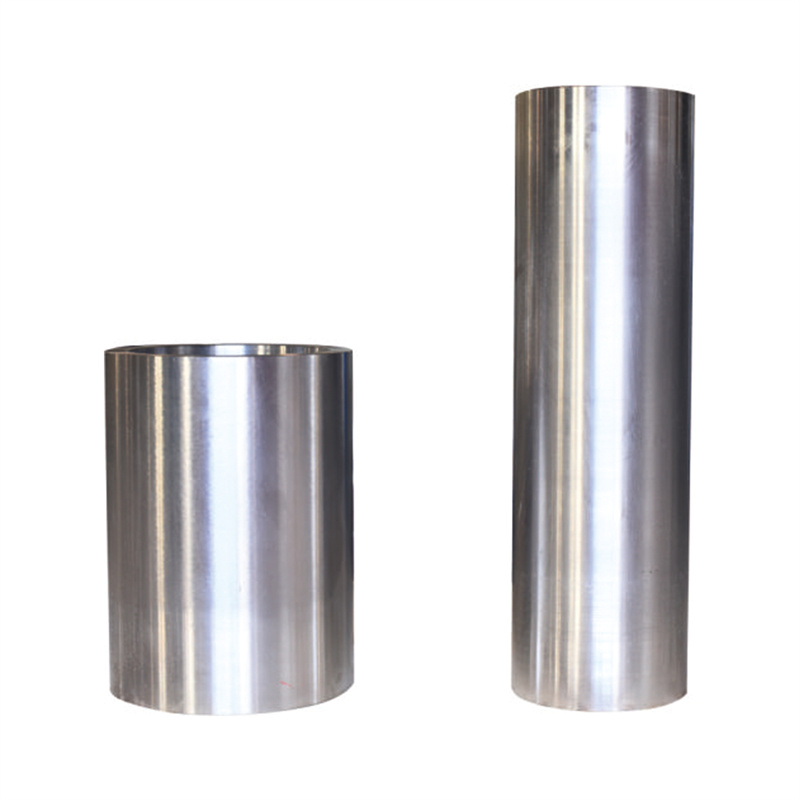

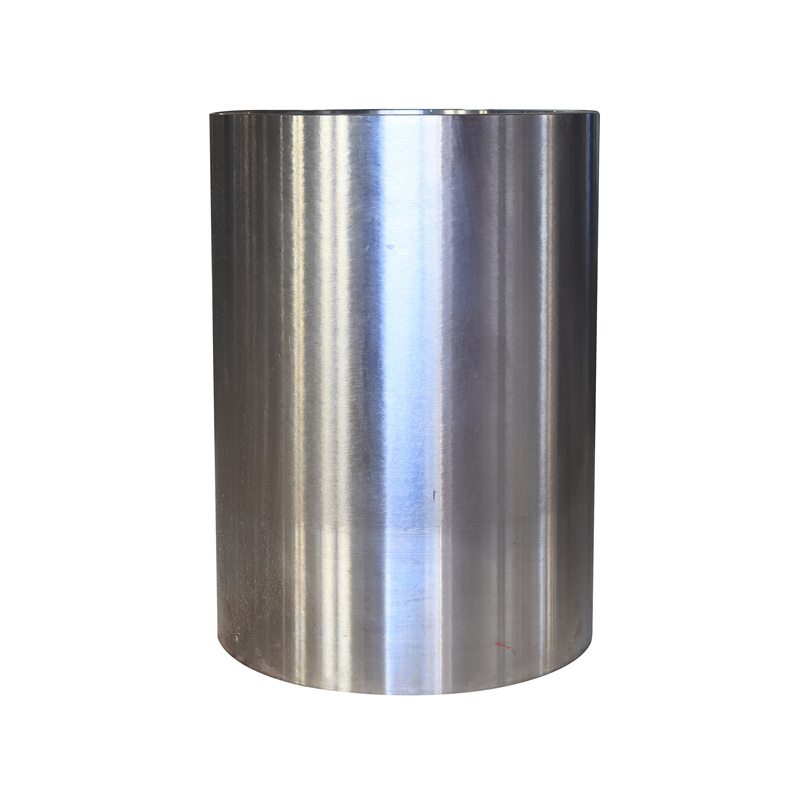

Machining

Weizhen is fully set up with advanced CNC and traditional machining facilities, covering all aspect of machining capabilities from cutting cutting, honing, drilling, turning, to milling and grinding. The products could be delivered as cast, rough machined or finish machined.

Inspection & Testing

Casting parts need to be tested and inspected before delivering to customer. Weizhen conducts strict checking and testing through out the whole production process to ensure best product quality and customer satisfaction. The tests and inspections Weizhen provides include, but not limited to, chemical analysis, physical properties, dimensions, PT, RT, three coordinates, 3D Scan, etc.